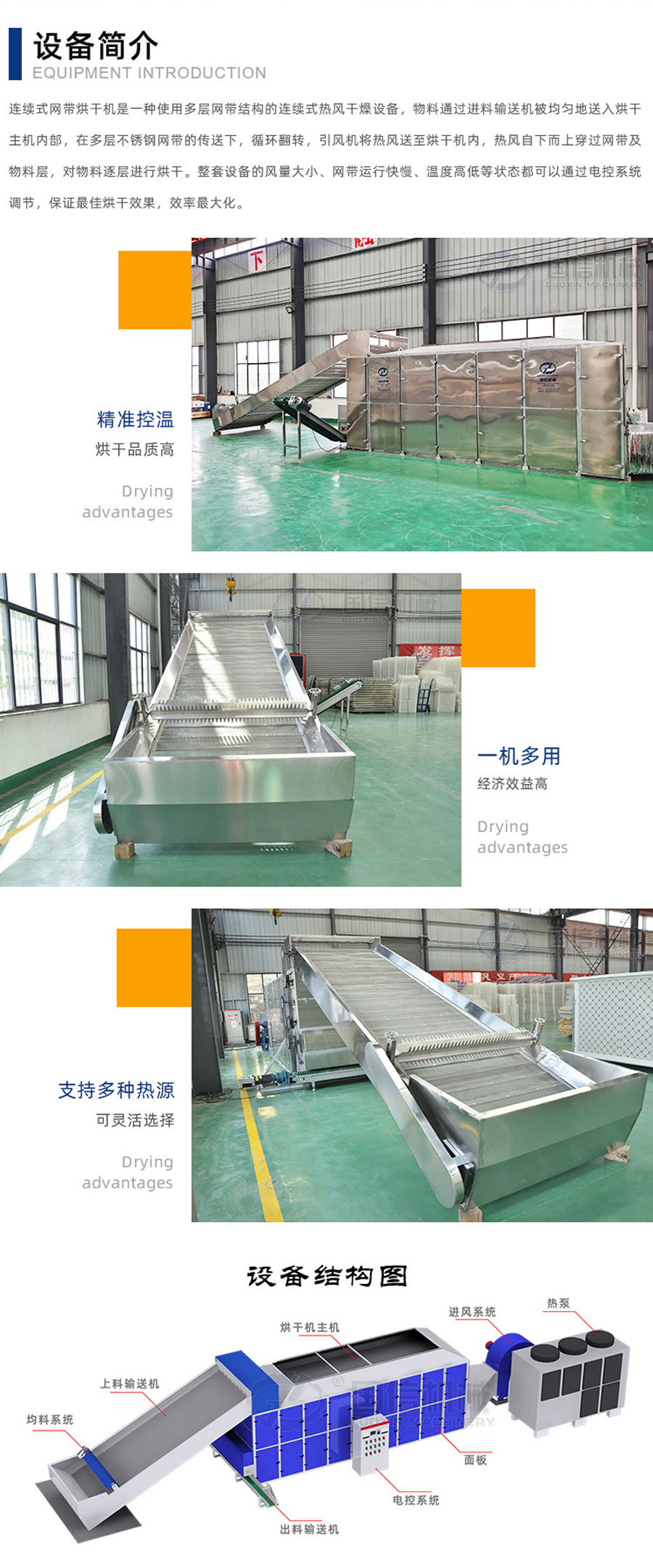

Description

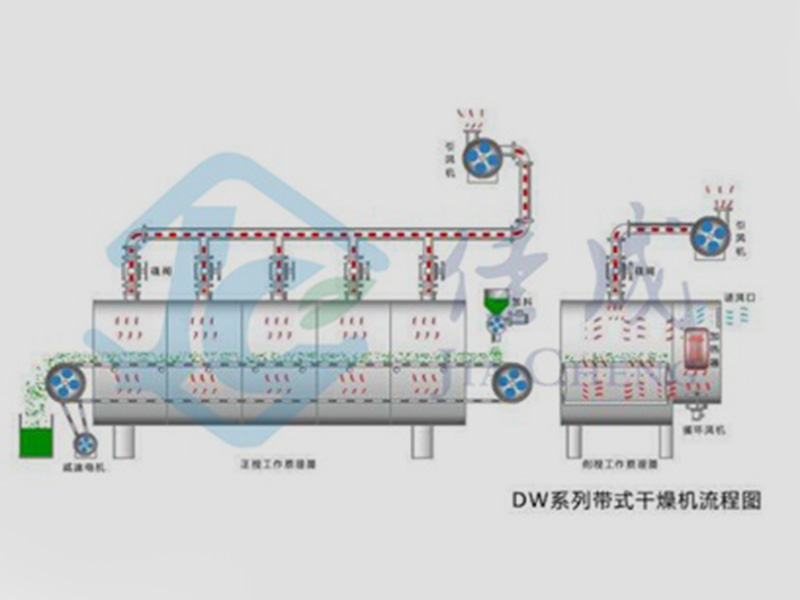

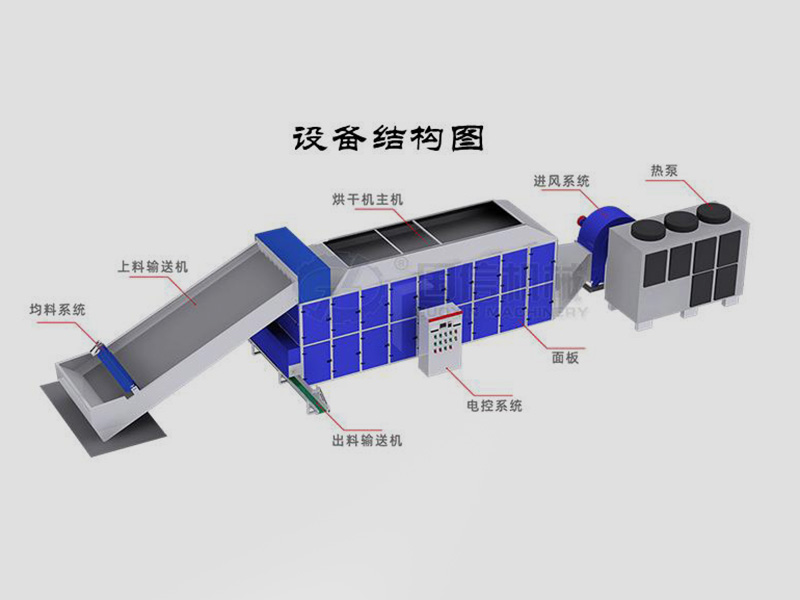

For dehydrated vegetables, belt dryers are generally used in series to form the initial drying section, the middle section and the final drying section. In the initial drying section, due to the high moisture content of the material and the poor air permeability, a thin layer thickness, a faster running speed and a higher drying temperature are used. If the material temperature is not allowed to exceed 60℃, in the initial drying section, the drying gas temperature can be higher than 120℃. For the requirement that the material temperature does not exceed 60 ℃, the drying gas of about 80 ℃ can be used, and the multi-stage combined belt dryer can be used to better exert the drying performance of the belt type and make the drying more uniform.

The belt dryer is suitable for the drying of garlic, carrots, white radishes, mushrooms, green vegetables, peppers and other vegetables; lumpy and large granular materials such as pumpkins, potatoes, ginger, Jerusalem artichoke, bamboo shoots, apples, and marine organisms. It is also suitable for drying Chinese herbal medicine slices, especially suitable for materials that do not allow high temperature drying. Vegetables with strong seasonality can be processed in time, which can avoid economic losses caused by seasonal storage pressure and abnormally rot and deterioration. The drying principle of the through-flow thermal cycle has good energy saving effect. At the same time, according to the moisture content of the material to be dried and the heat sensitivity of the material, the dryer can adjust the temperature and the speed of the mesh belt, so that the requirements for the color,taste and fragrance of the dried material will not change,taste quality requirements, maintaining the original quality of vegetables. Therefore, it has good economic and social benefits.

Advantages

◉ Air volume, heating temperature, material residence time and heating speed can be adjusted to achieve high-quality drying effect;

◉ Equipment configuration is flexible, and mesh belt washing system and material cooling system can be equipped;

◉ Most of the air is recycled, highly energy saving;

◉ The unique air distribution device makes the hot air distribution more uniform and ensures the consistency of product quality;

◉ The heat source can be equipped with steam, heat-conducting oil, electricity or coal-fired (oil) hot blast stove;

◉ The vibration and impact of the material on the belt dryer are slight, and the material particles are not easy to be pulverized and broken, so it is also suitable for drying some materials that are not allowed to be broken;

◉ The belt dryer is not only used to dry the material, but also to bake, sinter or ripen the material sometimes;

◉ The structure of the belt dryer is not complicated, the installation is convenient, and it can run for a long time. When a fault occurs, we can enter the inside of the cabinet for maintenance, which is convenient for maintenance.